NEWS

NEWS

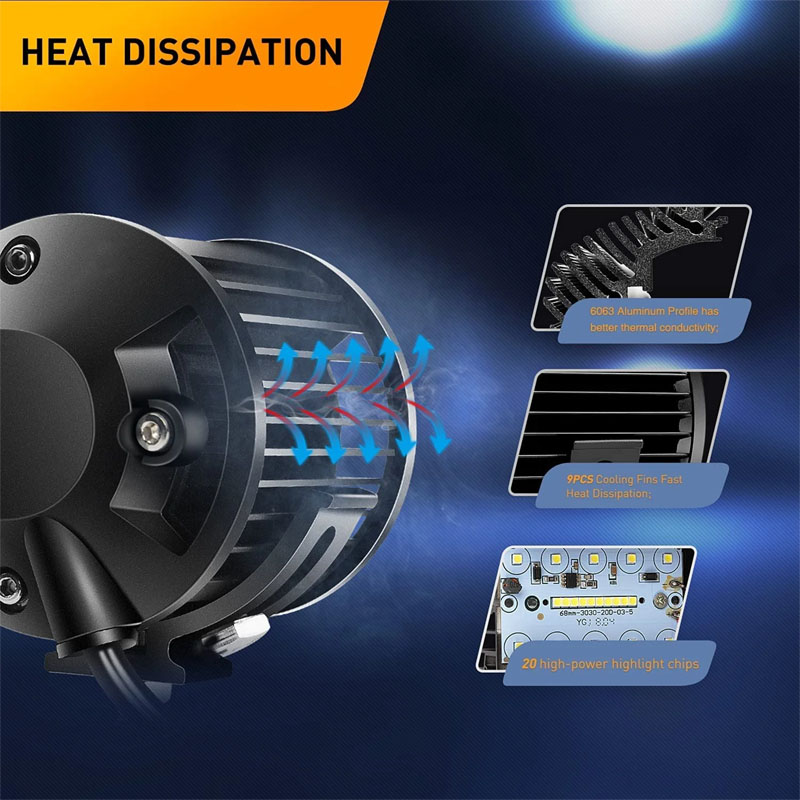

What can the temperature control component do to improve the heat dissipation of laser led pod light

22-11-2025

Temperature control components can improve the heat dissipation on aluminum housings of laser pod lights greatly by enabling active cooling, which provides a much more stable and efficient way to manage heat than passive methods alone.

Temperature control typically involves a closed-loop system that measures the temperature of inside pcbas and adjusts the actual power consumption output in real-time according to the set starting temperature degree.

Based on the primary active cooling mechanism,a TEC is a small, solid-state, ceramic-based component that acts as a heat pump based on the Peltier effect.When an electrical current is applied, one side of the TEC gets cold, actively drawing heat away from the laser diode. The other side gets hot, where the absorbed heat is transferred to the exterior aluminum housing in terms of heat sink for dissipation into the environment. TECs allow the laser lamp to be cooled below set temperature point and provide fast, precise control for maintaining a specific, safe operating temperature. The temperature controller as the "brain" of the system, which constantly monitors the temperature and regulates the electrical current sent to the TEC. It adopts algorithms (like PID—Proportional, Integral, Derivative) to quickly respond to temperature fluctuations. If the laser lamp starts to heat up, the controller increases the current to the TEC to boost cooling. If the laser gets too cold, it can reduce the current or even reverse it to apply slight heating, ensuring the temperature remains in a narrow, optimal window. In doing so, it can provide exceptional temperature stability , eliminating the gradual thermal rise on exterior heatsink. Also, a highly sensitive component (usually a thermistor, RTD, or thermocouple) is placed in close proximity to the laser chip. It provides the real-time feedback loop to the controller, allowing the system to accurately measure the lasers temperature and respond instantly to any changes in the heat load.

Temperature control components facilitate active cooling. Stable temperature guarantees consistent light quality and stable output power. By actively holding the temperature at a lower, safe point, the controller dramatically extends the laser pod lights operational life.

Active cooling can remove far more heat than passive methods only by heatsink, allowing the laser lamp to be driven at higher power levels without exceeding its safe thermal limits. The system can maintain the optimal laser lamp performance regardless of the external temperature in summer.